- Taizhou Huangyan Yuanda Machinery Manufacture Co.,ltd.

YD-5000 Automatic servo motor blow moulding machine

YD-5000 Automatic servo motor blow moulding machine

1.High quality compact machine Most popular pet bottle blowing machine YC-9000 With touch screen, Use Festo ( German brand) , SMC (Japan brand ) & Parker ( U.S.A Brand) pneumatic components. PLC use Mitsubishi (Japan brand)

2.Nontoxic conveyor belt to carry preforms

3.Produce PET Bottles ( such as: wine, beverage, soybean, vinegar bottles and so on)

4. Easy to maintain

5. Infrared lamps

6.High safety. high speed with high efficiency.

7.Manual saving, one man is enough for operation the machine.

8.Stable performing with easy maintaining.

9.Imported PLC controlling and man-machine interface computer.

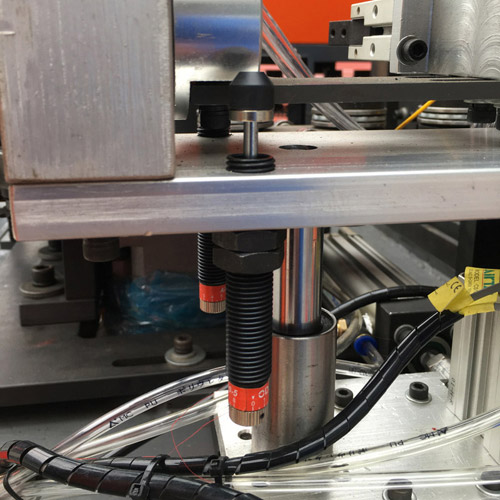

10.Japan Omron inspection sensor.

11.Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

12.Power saving design that can increase your profits.

13.Segregate type air controlling system, which is designed for avoiding waste pollution.

Description

YD series linear bottle blowing machine features:

stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

3. servo transmission system, high positioning accuracy, fast speed, good stability and reliability.

4. suitable for flexible production of small quantity and various bottle shape,wide range of applications,meet customer needs.

5. increase energy using efficiency,increase productivity per unit of time.

6. manual and automatic methods of operation, human-machine interface control, simple operation.

7. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

8. safety self-locking device in each mechanical action,when a certain process fails, the program will automatically switch to a safe state.

9. less than 0.2% scrap rate for finished bottle .

| General Information | YD-5000 4 cavity |

| Clamping Force | 40T |

| Clamping Stroke | 125mm |

| Max.Stretching Stroke | 400mm |

| Bottle Moving Stroke | 0-50mm |

| Cavity No. | 4cavity |

| Output | 4000-5000BPH |

| Max.Mould Thickness | 300mm |

Space Between Tie Bars | 100mm |

| Mould Plate Size | 670x650mm |

| High pressure Air compressor | 4.8m3/min 3.0Mpa |

| Low pressure Air compressor | 1.6m3/min 1.0Mpa |

| Voltage Standard | 380V/3PH/50Hz |

| Heating Zone No. | 4 Sections |

| Total Power | 50KW |

| Bottle Volume | 0.1-2.0L |

| Neck Diameter Range | 16-38mm |

| Max.Bottle Diameter | 115mm |

| Bottle Height | 360mm |

| High-pressure System | 3.0-4.0Mpa |

| Low-pressure System | 0.8-1.0Mpa |

| Machine Size | 355x160x200cm |

| Auto-loader | 110x120x220cm |

| Net Weight | 3.8T |